Solid Fuel Boiler Sections:

MOSS Biomass Boilers

Professional Industrial biomass boiler systems. Contact us for info!.

BiomassBoilers.com

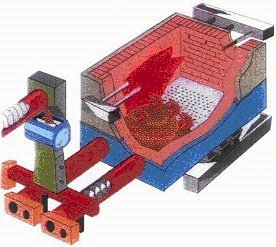

Biomass Combustion Chambers

Gasifier System

The Moss gasifier combustion system can burn wet or dry biomass fuels very efficiently while providing excellent emissions. Moss combustion systems are capable of burning numerous biomass fuels some of which are listed below. Our gasifier design minimizes particulate carryover from the combustion chamber, while promoting low NOx and CO emissions. Because of today’s MACT and BACT air emission regulations, the Moss gasifier system provides the lowest emission discharges in the industry. If the fuel to be burned is below 10% moisture content, our gasifier design promotes superior safety and helps prevent a “blow back” from occurring that may cause a fire in the biomass storage facility. Not all combustion chamber designs can burn dry fuels safely.

Each gasifier design is designed with large furnace volumes (generally providing 22,000 BTU/cu. ft. of heat release or less) with multi-zone grate underfire air, multi-port and multi-zoned overfire air systems with high turndown capabilities powered by our superior combustion control system. Our gasifier system can be installed on any of our boiler systems, customers existing firetube or watertube boilers or on direct fired lumber dry kilns, cement kilns, grain or wood dryers or any other direct fired device. The gasifier system is provided with or without automatic ash removal from the gasifier chamber.

Pneumatic Spreader Combustion System When burning wet fuel, we suggest that a combustion air preheater system be provided in order to drive off moisture quickly once the fuel is injected into the combustion chamber. Preheating the underfire air to approximately 300° F. or more is recommended. Preheated combustion air greatly improves the combustion process when burning wet fuel in our pneumatic spreader system. The pneumatic combustion system injects air into the chamber in two (2) points - forced draft fan provides underfire air under the grate and the overfire air fan assembly provides air to various headers located above the grate to ignite unburned gases and particulate that is burned on the grate. The pneumatic spreader combustion system is very flexible when burning fuels with various moisture contents and weights. These fuel variations could be due to the changing of the species of biomass being burned. If the fuel supplied to the combustion system varies in moisture content or BTU’s, these variations can cause major problems with some combustion systems. The Moss pneumatic combustion system is the best system to overcome these possible variations in fuel supply or operating parameters.

The Moss pneumatic biomass combustion system uses a pneumatic blower to transfer the fuel into the chamber where some of the fuel is combusted in suspension with the balance falling to the grate where it is completely burned. The pneumatic spreader combustion system can be used on the hybrid, watertube and firebox boiler designs and can release heat quickly to the boiler so that steam pressure drops are prevented. The Moss pneumatic spreader combustion system can burn dry or wet fuel.

Listed below are some of the biomass fuels applicable for burning in our combustion systems:

Animal by products

Coffee Grounds

Corn (Shelled)

Corn Bran

Corn Cobs

Corn Stover

Coconut Hulls

Oat Hulls

Peanut hulls

Pecan Shells

Poultry litter

Rice Husks

Wheat Bran

Wood